Vous visitez le site Web Canada Kee Safety depuis United States. Voulez-vous aller sur le site de {l'autre pays} ?

Vous visitez maintenant la version française du site Web de Kee Safety.

The anchor on a newscast is the trusted voice of the station. You can count on the anchor to give you the news straight up and accurately. The anchor will not let you down.

The anchor on a rooftop will not let you down, either. Anchors that meet regulatory standards and are installed properly will stand up on the roof and tie down workers so they will not fall to a lower level and risk severe injury.

Roof anchors provide a secure connection for workers servicing HVAC systems and other equipment on the roof and for suspended scaffolds for window washing, painting, building façade restoration, and other maintenance or construction tasks.

National, provincial, and territorial standards address the need for roof anchors used with “active” fall protection systems and equipment, notably lifelines. Compliant anchors can be permanent or temporary. Certified rope access and working at height training help provide trust in anchorage systems to secure worker safety.

According to Canada Occupational Safety And Health Regulations, SOR/86-304, Sections 12.09, if there is a risk of injury due to a fall in the workplace, a fall protection plan needs to be in place, and the employer must provide personal fall-protection to every worker at risk.

Components of a system include body belts, self-retracting devices, descent devices, fall arresters and vertical lifelines or rigid rails, a full body harness, energy absorber and lanyards, connecting components, and anchorage connectors (k) Z259.15.

Provincial and territorial standards for anchor strength (load capacity) vary between jurisdictions, ranging from 16 to 22.2 kilonewtons (approximately 3,600 to 5,000 lbs.) or withstand at least two times (or more) the maximum arrest force in any direction.

Ideally, permanent roof anchors are factored into new building construction; however, retrofitting a rooftop with anchorage devices is readily accommodated. Permanent anchors can be used on flat or low-slope roofs, BUR membrane systems, single-ply membranes, modified bitumen, green roofs, and metal roofs with underlying structures of steel, concrete, or wood. They can be bolted on or around, cast or epoxied in place, or welded on.

For code compliance, the anchors should be manufactured from a 4.5” OD structural steel tube with a 5/8” thick baseplate, both galvanized for durability and corrosion resistance. Insulated anchor posts will prevent condensation that can cause corrosion and stop heat from leaving the building through the anchor. The location of the anchorage points on the roof should be based on where workers need access and an acceptable range of the tie-off system.

Certified anchor bolt training will enable personnel to install, test, and inspect permanent anchor devices. Course instruction covers the roles and responsibilities of the system designer, installer, inspector, and user, and documentation after installation and inspections.

Where permanent anchors are not installed, mobile roof anchors provide a compliant safety solution for workers on the roof. Instead of being mounted into the roof, the eyehole post—to connect the lifeline—is anchored by deadweights placed on the roof when and where needed.

This makes the mobile anchor non-penetrating of the roof and ideal for use on flat and low-slope roofs of single-ply membrane, asphalt, mineral felt, concrete, or brushed stone chippings. With more than 100 suction cups molded to each rubber-bonded weight, the anchorage system is designed to maximize grip and stay in place. Galvanized steel treatment makes the system corrosion resistant.

These mobile anchors are not designed to have workers go over the side of the roof to paint, wash windows, or repair façades. Such tasks are best performed using scaffolds suspended from permanent anchors or an innovative new mobile rope access anchor.

A mobile rope access anchor builds on a mobile roof anchor by incorporating a steel track that allows a single user to rappel down the side of the building. As with permanent and mobile roof anchors, it must be compliant with CSA Z259.15-17 anchorage connectors and meet the recommended load rating of 22.5 kilonewtons (5,000 lbs.). Like the mobile anchor, the mobile rope access anchor is non-penetrating of the roof and galvanized for corrosion resistance.

Certified working-at-height training covers a range of fall protection legislation and the installation, testing, and operation of fall protection equipment. Coursework includes a comprehensive review of anchor types and systems and the selection of anchor points.

Rope access training based on the International Rope Access Trade Association (IRATA) certification is further recommended, especially for workers who are using a rope/lifeline system to access the vertical sides of a building, storage facility, or other type of structure. Level 1 training is specifically designed to enable a worker to perform a range of rope access maneuvers, inspect their equipment, assist with rigging (under supervision), and undertake a self-rescue if necessary.

A news anchor sits with ramrod posture in a chair behind the news desk, confident that the information being conveyed is fair and honest. Construction and maintenance workers can be just as confident of being protected against a fall when they know that they are being anchored by a strong and compliant permanent or mobile roof anchor. And that they are well-trained to inspect and use their full range of fall protection equipment.

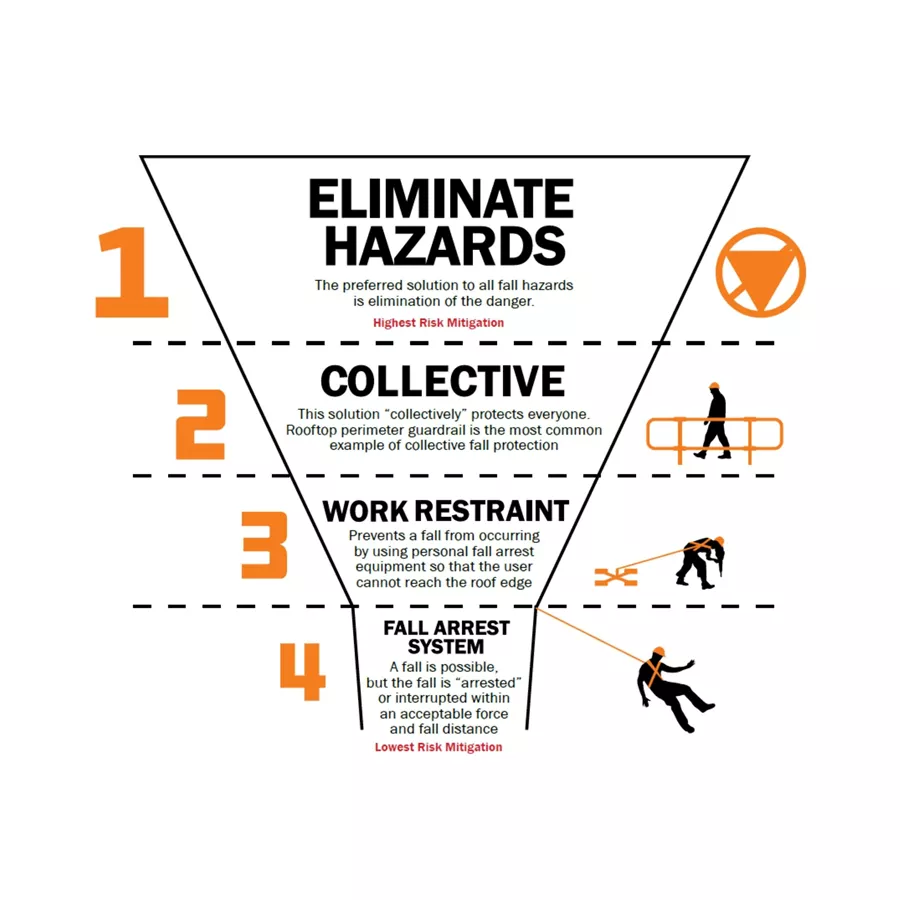

A truly comprehensive rooftop solution follows the Hierarchy of Fall Protection. An expert starts by inspecting the roof site for potential fall hazards. From there, a complete system solution and recommendations are created that descend down the four levels of the hierarchy, from simple, sensible approaches for eliminating risks all the way down to lifesaving personal protection systems.

Collective Systems require no additional training to use. Fall Restraint and Fall Arrest Systems both require a high level of user competency, training and additional inspection to be used properly.