Vous visitez le site Web Canada Kee Safety depuis United States. Voulez-vous aller sur le site de {l'autre pays} ?

Vous visitez maintenant la version française du site Web de Kee Safety.

Industries rise and fall due to technology—the automobile replacing the horse-drawn buggy is a favorite example—or relocate to another country because of lower labor costs, better access to raw materials, fewer regulations, and so on.

An industry not going anywhere found in virtually every Canadian municipality is wastewater treatment. These unique, ubiquitous facilities clean sewage and treat used water so that reoxygenated water can be returned safely to the environment.

Another aspect of safety at a wastewater treatment plant is safeguarding the workers, including fall protection.

What is often most noticeable at a wastewater facility is the number of railings installed around clarifiers, vats, and tanks, along walkways, and even on the roofs of buildings. The preferred type of railings used for water storage and processing areas are constructed of aluminum or an aluminum alloy for strength, durability, and corrosion resistance.

The preferred aluminum railings are modular, pipe-fitted systems because they require no welding to install and are easy to reconfigure for changing facility needs. As an added safety measure, railings equipped with toe boards can help prevent tools from falling into the water.

According to Canada Occupational Safety and Health Regulations, SOR/86-304, Sections 12.12 (guardrails) to 12.13 (toe boards), guardrails should be highly visible and have:

Railing systems have entry points, notably for stairs, roof access, machine guarding, and other restricted areas. To protect workers from a fall or unauthorized entry, install self-closing gates. The gates should also be constructed of aluminum and meet the same regulatory safety standards for railings.

Railings and gates protect workers in the event of a fall; however, an anti-slip safety walkway can help prevent a fall. Walkways made from nylon or aluminum will not rust, are installed without welding, and can be configured to traverse areas from the ground floor to rooftops. They can be constructed as steps for inclines or crossovers for obstacles such as pipes.

Wastewater treatment plants have skid-mounted processing systems and building support equipment (e.g., HVAC) that require maintenance and repairs. Work platforms are more stable and safer than ladders. Constructed with modular fittings, bases, and frames that connect pipe rail, steps, and anti-slip surfaces, a significant advantage of these work platforms is that they can be reconfigured when needs at the plant change.

Platform types include:

Not all tanks, processing systems, or vehicles can be serviced from the side or at level, so overhead fall protection equipment will be needed, such as horizontal lifelines or overhead lifelines that provide access from above. In the event of a slip or fall, lifelines provide fall arrest to help prevent a worker from injury.

A wastewater treatment plant is a dynamic, ever-changing facility where construction crews are often present for renovations or a new build. There are many safety regulations to cover the construction industry, but for other employees, a warning line will highlight an off-limits area at the facility.

A warning line should not simply be a roll of caution tape. A proper demarcation system will have strong, sturdy, adjustable bases, uprights, and cables marked by large safety flags. The portability of such systems is ideal for a facility in a constant state of progress.

The average person may not think of wastewater treatment plants as they shower, run the dishwasher, or flush the toilet. In addition to residences, large amounts of wastewater are generated by manufacturing facilities, food processing plants, the pharmaceutical industry, medical and educational institutions, and many other segments.

While wastewater treatment may be the last thing people think about, every locality depends on these facilities. And like everywhere else, safety comes first.

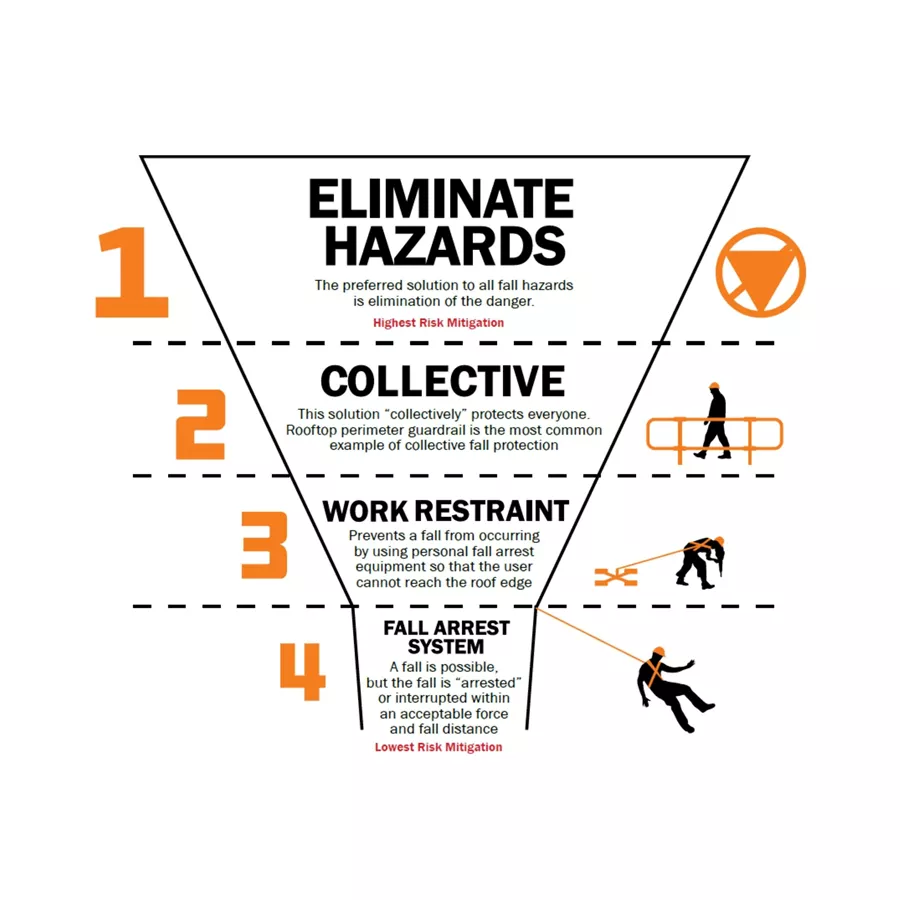

A truly comprehensive rooftop solution follows the Hierarchy of Fall Protection. An expert starts by inspecting the roof site for potential fall hazards. From there, a complete system solution and recommendations are created that descend down the four levels of the hierarchy, from simple, sensible approaches for eliminating risks all the way down to lifesaving personal protection systems.

Collective Systems require no additional training to use. Fall Restraint and Fall Arrest Systems both require a high level of user competency, training and additional inspection to be used properly.