You are visiting the Canada Kee Safety website from United States. Would you like to go to the United States site?

When it comes to a facility’s fall protection, workers who access the roof for inspections, maintenance, repairs, and other tasks are often in the spotlight. Although a slip and fall resulting in an injury can occur almost anywhere in a building, a fall from an unprotected roof edge would be devastating.

An engineered horizontal lifeline system is a regulatory-compliant way to provide both fall restraint and fall arrest for rooftop workers and others who need to move along an elevated surface. An anchorage system that complies with national, provincial, and local safety standards is critical to any lifeline assembly.

The modular design of a horizontal lifeline system allows it to adapt to different worksite requirements and integrate seamlessly with existing structures. It provides continuous protection for workers, allowing them to remain securely attached while performing their tasks. Horizontal lifelines feature galvanized and stainless steel components for strength, durability, and corrosion resistance. A span of nearly 12 metres (39 feet) between anchor posts can support up to three workers.

The energy-absorbing lifeline offers versatile mounting options:

A rigid anchor with a horizontal lifeline bracket is a permanent solution to secure the system and protect workers. It is adaptable to various roof types, including flat or low-slope roofs, BUR membrane systems, single-ply membranes, modified bitumen, green roofs, and metal roofs. The anchor posts can be attached using several methods, such as bolting, casting in place, and welding, ensuring they can meet the specific requirements of different structures.

For flat and low-sloped roofs, an alternative to permanent anchor posts is a deadweight anchorage that rests on the roof instead of being installed into the structure. It features rubber-coated base weights with suction cups for added friction and is suitable for single-ply membrane, asphalt, mineral felt, concrete, and brushed roofs. A wet surface will not affect its steadfast performance.

Galvanized steel connectors link the four base weights and a central anchor post that houses a horizontal lifeline bracket. The anchor system is easy to install or disassemble, making it easy to move if the horizontal lifeline system needs rearranging.

Investing in reliable fall protection systems is crucial for maintaining safety at working heights. An engineered horizontal lifeline system with proper anchorages will provide fall protection for workers to perform various tasks on the rooftop and elevated areas throughout a facility.

By choosing the right system, companies can ensure the safety of their workers and comply with stringent safety regulations. Horizontal lifelines are a robust fall protection solution for temporary tasks or permanent installations.

Freedom to Work. Securely Attached. The Kee Line horizontal lifeline system is designed to provide workers with freedom of movement on the rooftop while securely attached to the lifeline at all times.

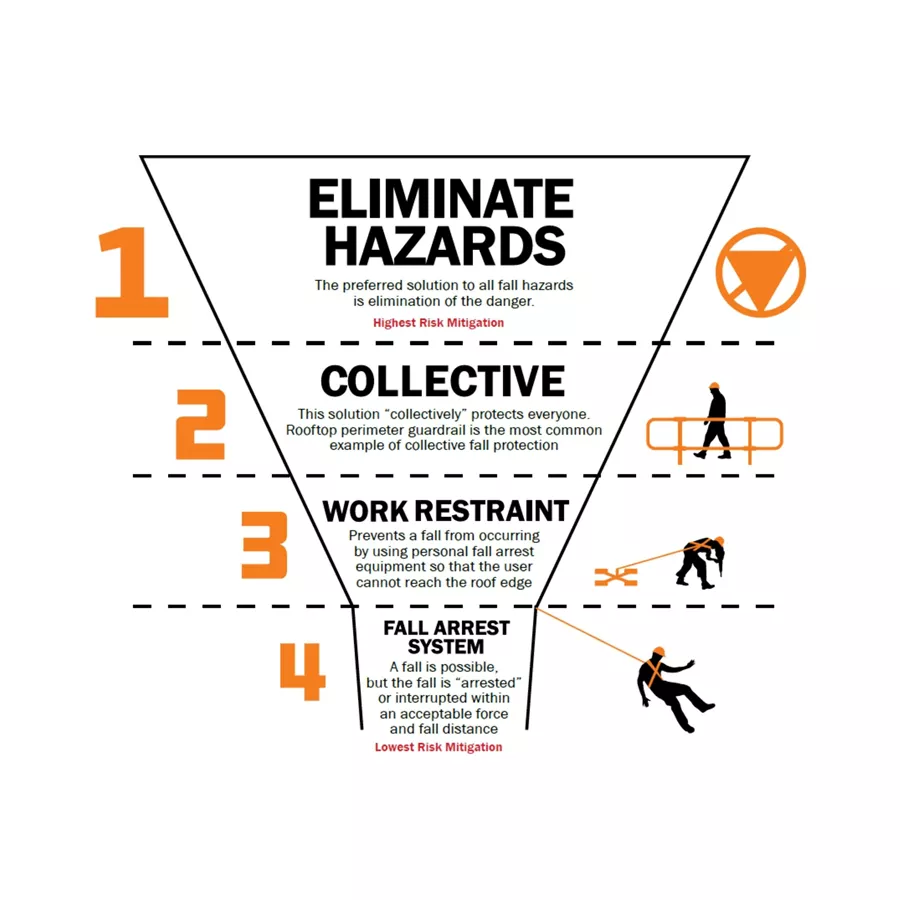

A truly comprehensive rooftop solution follows the Hierarchy of Fall Protection. An expert starts by inspecting the roof site for potential fall hazards. From there, a complete system solution and recommendations are created that descend down the four levels of the hierarchy, from simple, sensible approaches for eliminating risks all the way down to lifesaving personal protection systems.

Collective Systems require no additional training to use. Fall Restraint and Fall Arrest Systems both require a high level of user competency, training and additional inspection to be used properly.