You are visiting the Canada Kee Safety website from United States. Would you like to go to the United States site?

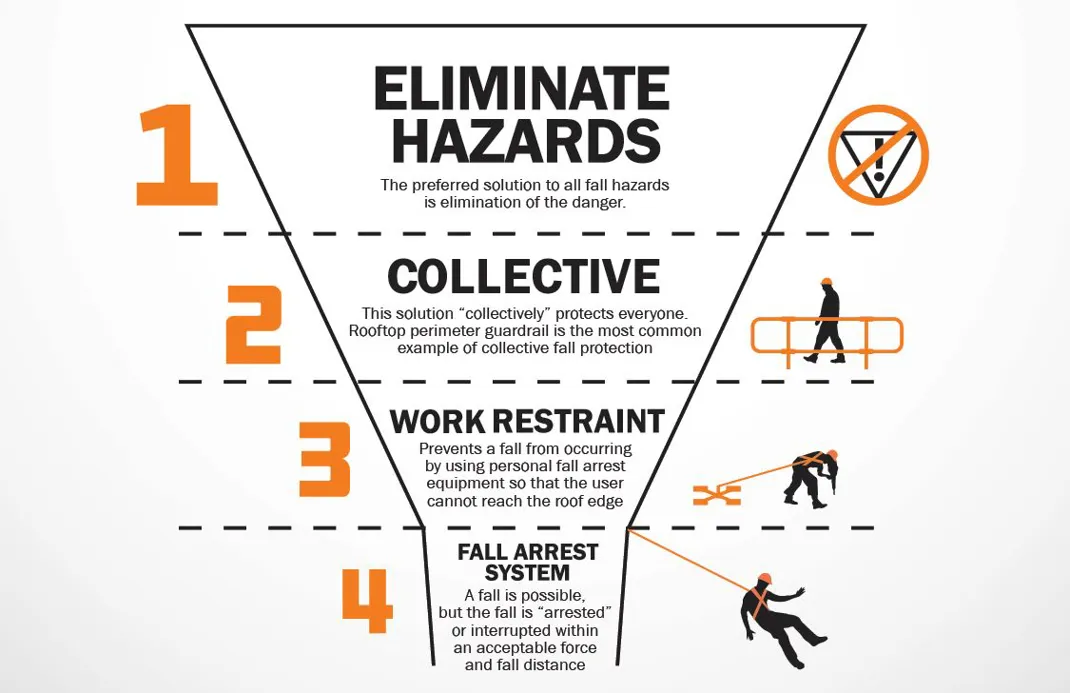

When talking about fall protection solutions, many people tend to go directly to “tying-off”. Granted, it is a well-known and often-used solution, but it is by no means the first solution that should be discussed when determining what methods will be used on a given job or for a given task. In fact, there is a hierarchy of solutions that should always be evaluated – in order – to determine which is the safest, most effective one.

There is no safer, more effective way to protect an employee from a fall than to remove the fall hazard itself. There are a number of ways this can be accomplished, such as changing the work so that the employee does not need to work at heights or by erecting a scaffold or some other system that protects the edge that was previously in question. Granted, these solutions are not always feasible or cost-effective (is it worth erecting a scaffold around a roof perimeter so that a maintenance worker can change one air-handling unit filter?), but they do need to be considered. If there is no fall hazard, there’s no fall.

The second most effective fall protection solution is one which requires as little employee thought or action as possible. This type of solution is a collective solution – a solution that protects all workers at once, such as railings or barriers. Collective systems do not require users to do anything (such as put on a harness or secure a lanyard to an anchor point) in order to be protected, thereby leaving much less room for human error. These systems are also known as passive systems.

In situations where elimination or collective systems are not feasible, companies should look toward work restraint. Work restraint is the first example of “tying-off”, however it is still not the one most people think of. Work restraint uses personal fall arrest equipment (harness, lanyard, horizontal lifeline and anchor point) in such a way that the user cannot reach the edge. Because of this configuration, this type of “tying-off” prevents the user from falling in the first place. Sometimes, however, the restrictions associated with fall restraint prevent a worker from doing the work that needs to be done, or reaching an area he or she needs to reach, so companies cannot employ it as a solution.

When all other solutions are infeasible, a company must consider fall arrest. Fall arrest uses the same equipment as work restraint, however in this situation the fall protection equipment does not engage until after there has already been a fall. When it engages, the equipment slows the worker’s descent, bringing them to a safe stop. This is the least desirable choice for a number of reasons: 1) It’s the only system in which a fall needs to occur in order for it to work. Anytime that happens, there is room for equipment failure or user error that allows for injury to the worker. 2) Injuries can still be sustained in the fall even if the equipment works properly, such as from striking a lower part of the structure or internal injuries from arresting forces incurred on the body (both of these situations are more likely if the equipment wasn’t used properly – such as in a swing situation or where the allowed free fall distance was too great). 3) A rescue plan is needed. If a person who has fallen is not rescued quickly (sometimes a matter of minutes), they could suffer suspension trauma that could result in serious health issues, including amputations or death. In some circumstances, rescue is very difficult. And while there are some devices on the market that help to alleviate suspension trauma, they usually require an action by the user. If the user was unconscious prior to, or as a result of, the fall, or if they are simply too panicked to focus, using these devices could be impossible. Regardless, despite the disadvantages to this method, fall arrest is still a much more desirable option than a worker plummeting to his or her death.

Fall protection is not something that can be determined on the fly. Without being properly thought out, there is a good chance that the best solution will not be the chosen solution. Why skip right to slowing down somebody’s fall when you can eliminate the fall altogether? Companies need to take the time to sit down in the planning stages of their work to determine how workers are going to be protected at heights – and if those workers even need to be at heights in the first place. Falls continue to be the leading cause of death in construction - and one of the biggest contributors to workplace fatalities overall – year after year after year. Until fall protection consistently becomes more than an afterthought or a perceived nuisance, falls will continue to lead the statistics. Do your part to not allow your employees to become one of the statistics. Run through this hierarchy and provide them effective protection.