Stay on Track

You are visiting the Canada Kee Safety website from United States. Would you like to go to the United States site?

Kee Track® can be fitted using standard tools and lifting devices. A typical system can be up and running in a day.

Designed to be attached to existing roof purlins and secondary steel, no extensive engineering is needed.

If you need to rearrange your working environment, Kee Track® can be adapted by moving and re-configuring the modular design.

Kee Track® was designed and created by professional engineers and is backed by a global network of support.

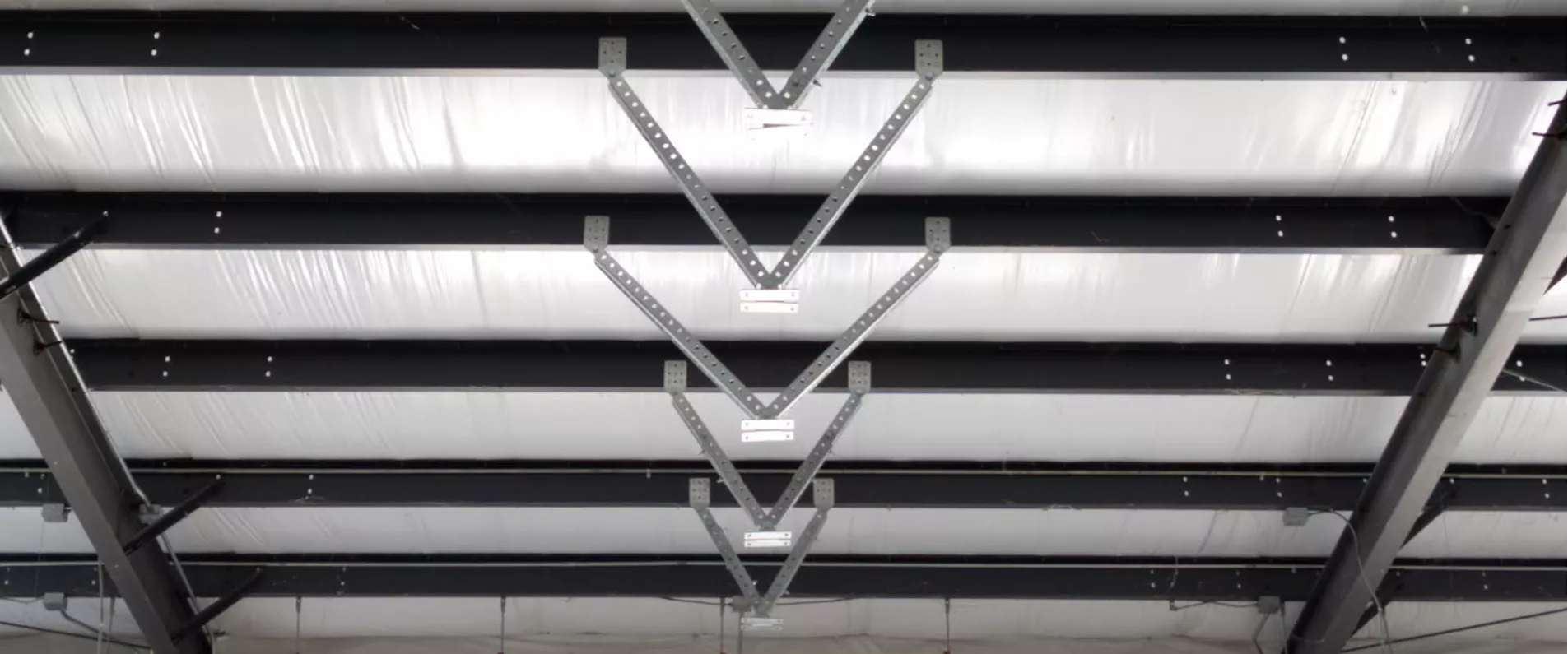

More often than not, floor space is precious. The Kee Track® system’s roof mounted lowprofile rails maintain an open floor plan for production, storage and material handling while providing exceptional overhead fall protection. The system complements warehouses and facilities with both high and standard roof heights. It requires no column supports and works around most roof infrastructures.

Protecting your most valuable assets - Whenever the distance required to stop a fall is small, a track system should be utilized. A short fall distance is not only vital for protecting an individual, but also the equipment being worked on. A fall on equipment such as an aircraft wing or delicate manufacturing equipment can result in expensive repairs.

One of the main advantages of Kee Track® is the unique range of mounting options. The system can be made secure to internal roof structures such as beams, trusses, and concrete. Where necessary, bespoke connectors can be supplied.

For primary and secondary steelwork: Kee Track works with the columns, rafters and bracing of primary steelwork, and the purlins of secondary steelwork.

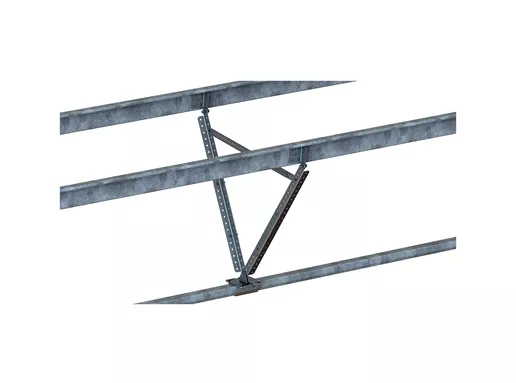

A parallel configuration positions the Kee Track® system in the same direction as the purlins.

A perpendicular configuration positions the Kee Track® system in the opposite direction of the purlins.

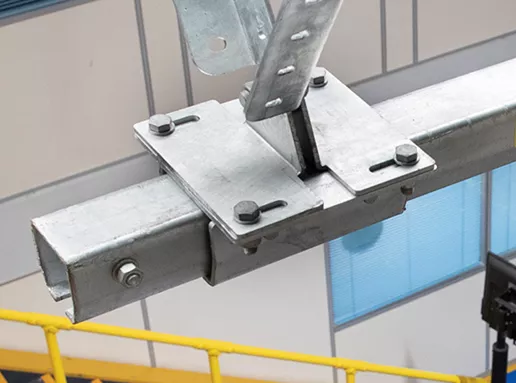

This patent-pending bracket allows for easier installation. Instead of threading the rail on the ground, the rail can be placed in position after the bracket is partially installed.

Kee Track® purlin bracketry allows the system to be attached in both a parallel and perpendicular format.

Our trolly has high-quality bearings to keep your system running smoothly for years to come.

| Document | Format |

|---|---|

| Kee Track Sales Brochure | |

| Kee Track Test Report & Instructions for Use Manual | |

| Kee Track Operation & Maintenance Manual | |

| Kee Track Technical Datasheets | |

| Kee Track Assessment Templates | |

| Safety Systems For Vehicle Maintenance | |

| Safety Systems for the Rail Sector | |

| Rooftop Fall Protection Solutions Brochure |

| Document | Format |

|---|---|

| Kee Track Sales Brochure | |

| Safety Systems For Vehicle Maintenance | |

| Safety Systems for the Rail Sector | |

| Rooftop Fall Protection Solutions Brochure |

| Document | Format |

|---|---|

| Kee Track Test Report & Instructions for Use Manual | |

| Kee Track Operation & Maintenance Manual | |

| Kee Track Technical Datasheets | |

| Kee Track Assessment Templates |

| Document | Format |

|---|---|

| Kee Track Test Report & Instructions for Use Manual | |

| Kee Track Operation & Maintenance Manual |

| Document | Format |

|---|---|

| Rooftop Fall Protection Solutions Brochure |

Canadian National Standards (CSA)

If I could choose which Rigid Track system to install I would pick Kee Track every time.Kee Track Partner, ITAC

While there are many obvious areas where fall protection is needed— rooftops, mezzanines—there are places where people work at height that don’t always get enough attention.

Kee Safety runs one of the world’s leading test and training centers at its UK headquarters. Run by a team of industry experts, this state-of-the-art facility ensures that Kee Safety products meet the needs of its customers. Kee Safety is committed to driving new innovation with the purpose of separating people from hazards.